The DMS Blog

A DMS Router is Behind One Entrepreneur’s Shark Tank Business

Tune in to Shark Tank this Wednesday, May 13th, to see entrepreneur Anthony Franco pitch his business, mcSquares, to the Sharks. mcSquares’ mission is to build human connections through the development of premium collaboration tools. Their primary product is a...

8 Manufacturing Trends in 2020

2020 will prove to be a pivotal year for manufacturing. We share some trends to watch for.

Preventative Maintenance Inspection Recommendations

**Perform these checks monthly to ensure that your CNC machine remains in optimal working condition.** • Inspect all machine electrical connections and air lines. • Check that proper voltage is connected to the machine (leg to leg, and leg to...

Hybrid Manufacturing Benefits – 5-Axis Possibilities

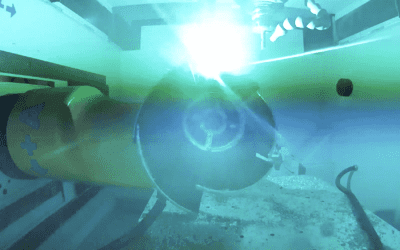

From 3 to 5-Axis in 30 Seconds on The Hybrid 2 Cubed At DMS we are committed to advancing metal-additive manufacturing. So we continue to push the envelope with our Hybrid additive/subtractive process, this time by adding 5-axis capabilities to our turn-key Hybrid 2...

Hybrid Manufacturing Benefits – Component Reduction

Designing a manufactured part from the ground up for hybrid manufacturing achieves the greatest benefits. We applied this concept to a low volume 5 axis yoke that we produce. Casting is traditionally the preferred method for producing these types of parts, but the...

Hybrid Manufacturing Benefits – Existing Part Spotlight

The redesign work to produce the part featured involves taking an existing design and making modifications suited for additive and hybrid processes. From this analysis, it was necessary to reduce the maximum build angle from 45º to 35º and reduce the thickness so that...

DMS Now Acquired By SCM Group

SCM Group acquires DMS, important US Player in plastics and composite materials applications Rimini, Italy / Colorado Springs, USA - November 26, 2018 - SCM Group, a leading Italian multinational company in machinery and industrial equipment, has finalized the...

How We Get Young Engineers Excited To Grow With Us

We all want to feel as if we are making an impact with our chosen career path. Young engineers have endless possibilities of how they can help society. In fact, in the Emerson Survey “3 out of 4 respondents said they believe that manufacturing jobs are important to...

DMS Completes Quick Change Fixture System

Diversified Machine Systems (DMS) completes industry changing Quick Change fixture system, now available on all DMS CNC routers. This revolutionary quick change fixture dramatically reduces the time required to swap out fixtures on all DMS 3 Axis & 5 Axis CNC...