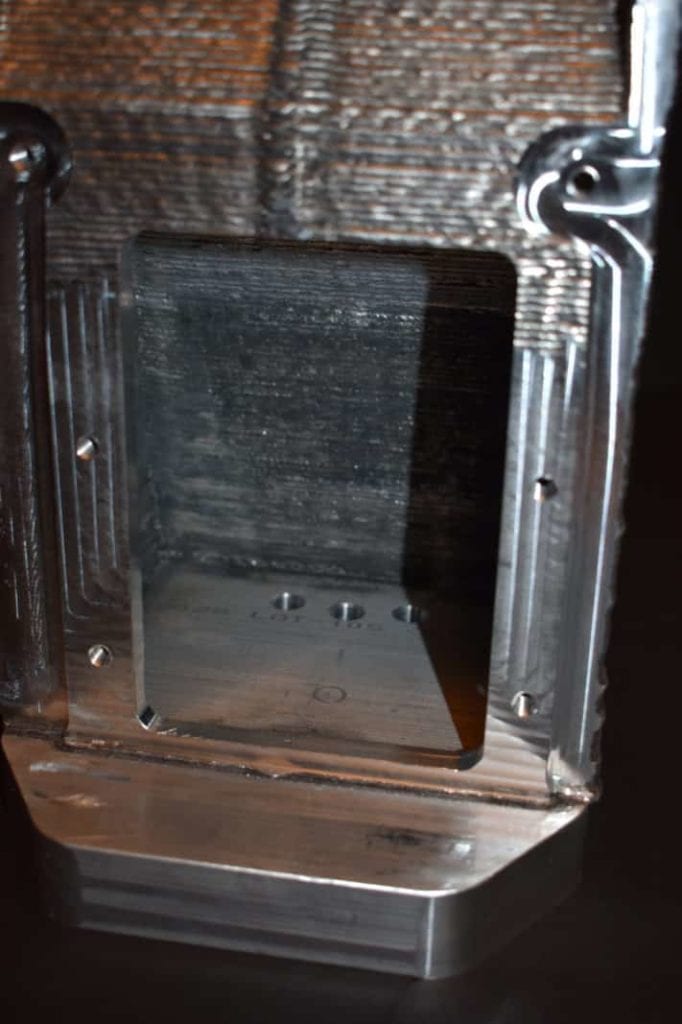

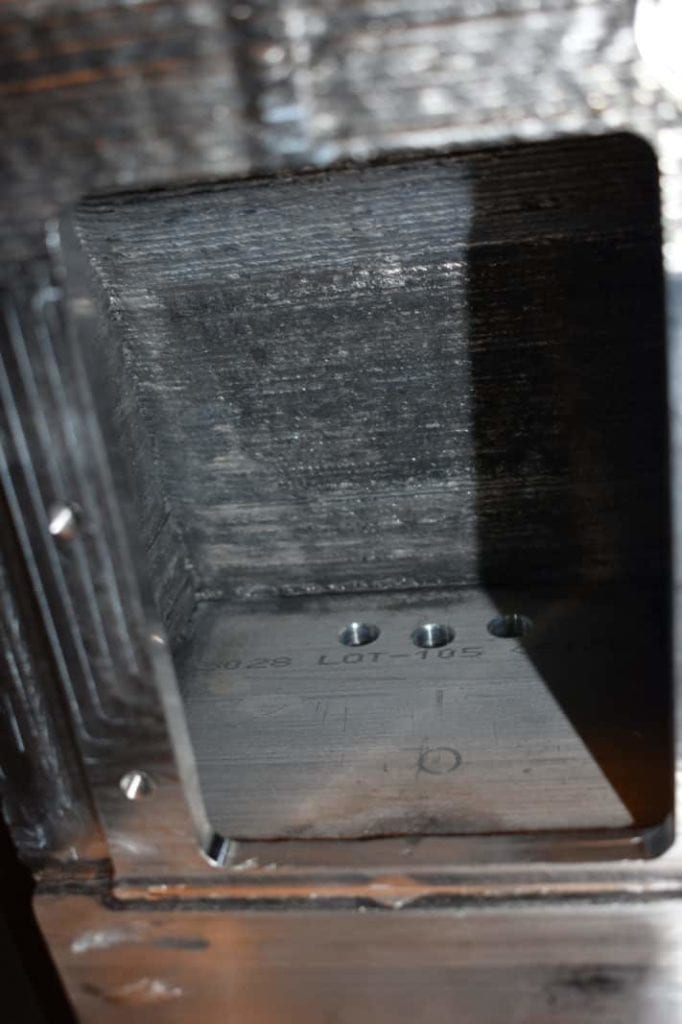

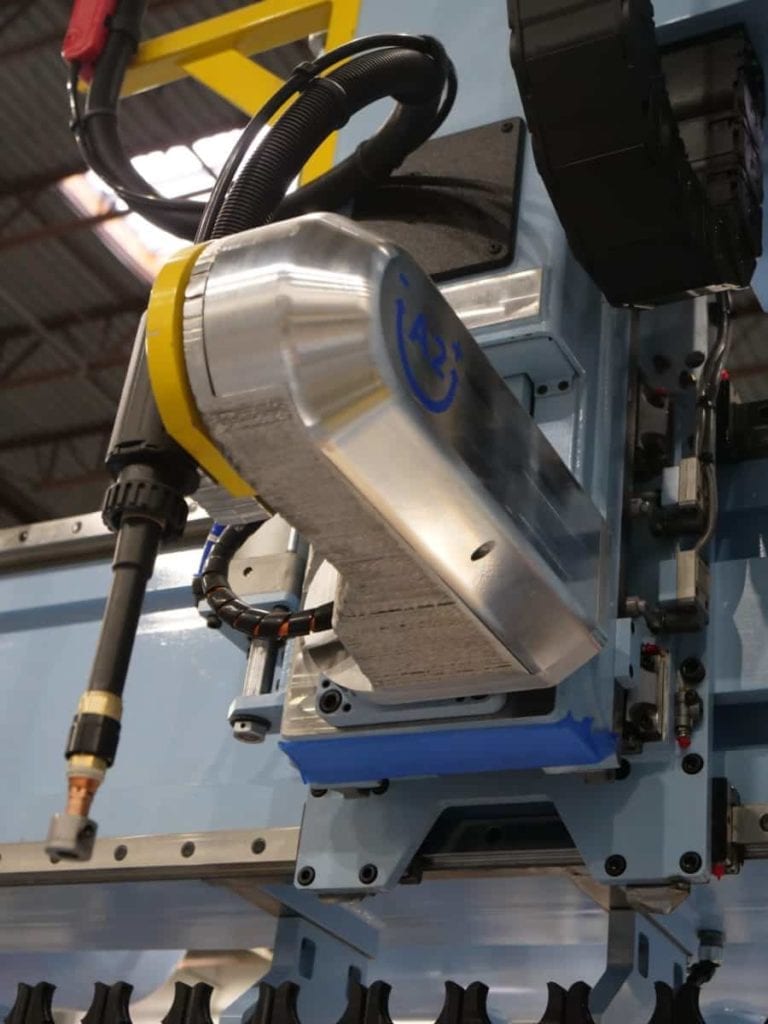

Designing a manufactured part from the ground up for hybrid manufacturing achieves the greatest benefits. We applied this concept to a low volume 5 axis yoke that we produce. Casting is traditionally the preferred method for producing these types of parts, but the low-volume, casting is not feasible.

It was redesigned to be manufactured with our hybrid process. This achieved a significant strength increase for the yoke and eliminated independent components and all fasteners. The finished part achieved higher precision by eliminating the tolerance stack-up inherit with multiple components. Assembly time was reduced and the potential for error removed.