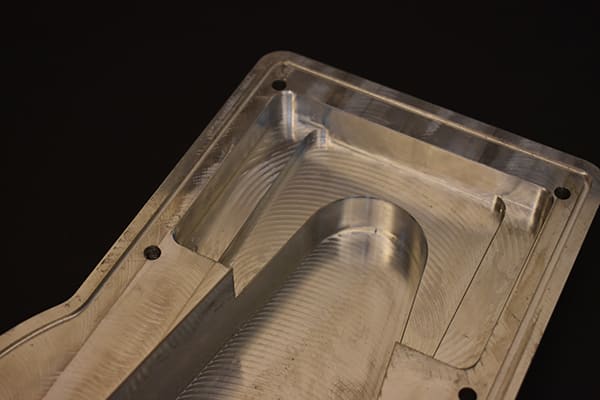

The redesign work to produce the part featured involves taking an existing design and making modifications suited for additive and hybrid processes. From this analysis, it was necessary to reduce the maximum build angle from 45º to 35º and reduce the thickness so that the part is equal to 1 weld bead throughout.

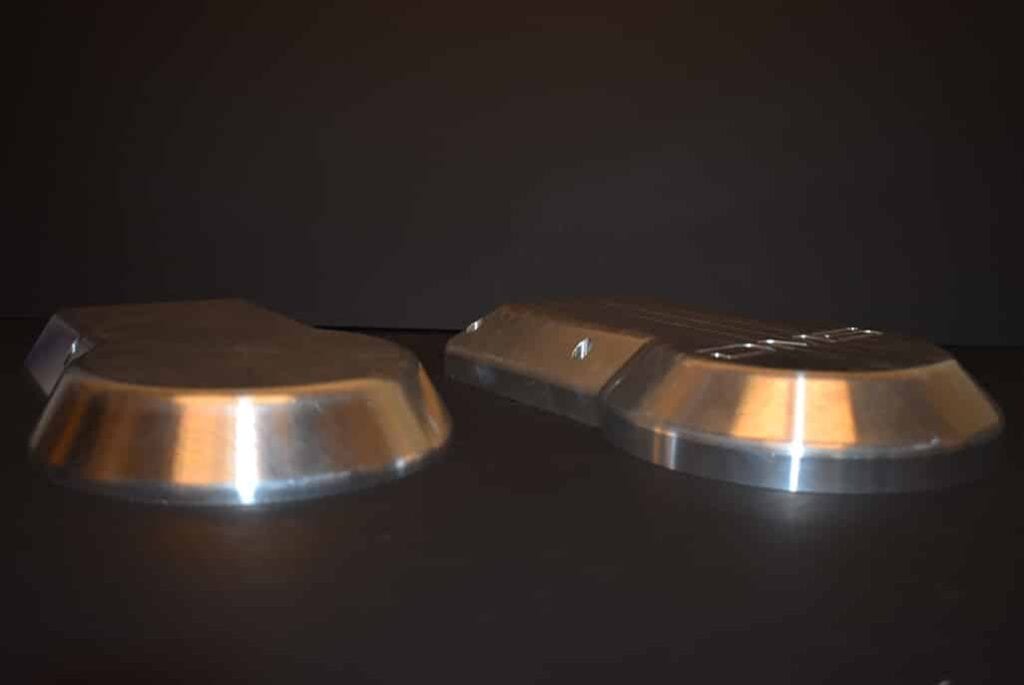

To showcase the differences between subtractive and our Hybrid processes, it took 23 pounds of material to produce the traditional yoke cover. Hybrid manufacturing required only 5.5 pounds of material. Compared to traditional manufacturing, the hybrid process is far more beneficial in using less raw material. Our Hybrid process reduced waste by over 75%. Keep that figure in mind next time you are recycling chips.

Click here for our selection of our Hybrid Machines.