2020 will prove to be a pivotal year for manufacturing. Below we share some trends to watch for. Because of the incredible impact of COVID-19 and the global pandemic, we have broken our list into the trends identified both prior and post Coronavirus.

Manufacturing Trends Predicted Pre-COVID-19

1. Manufacturers Will Build More Digital Muscle

From the Deloitte 2020 Manufacturing Industry Outlook report: “Applying artificial intelligence, cloud computing, advanced analytics, robotics, and additive manufacturing to the value chain can increase visibility and transparency, allowing manufacturers to make faster changes to operations to respond to market-based threats or opportunities. As manufacturers continue to seek out the bright spots in the global landscape— including emerging markets—their ability to flex production, delivery, and customer support will continue to be important.”

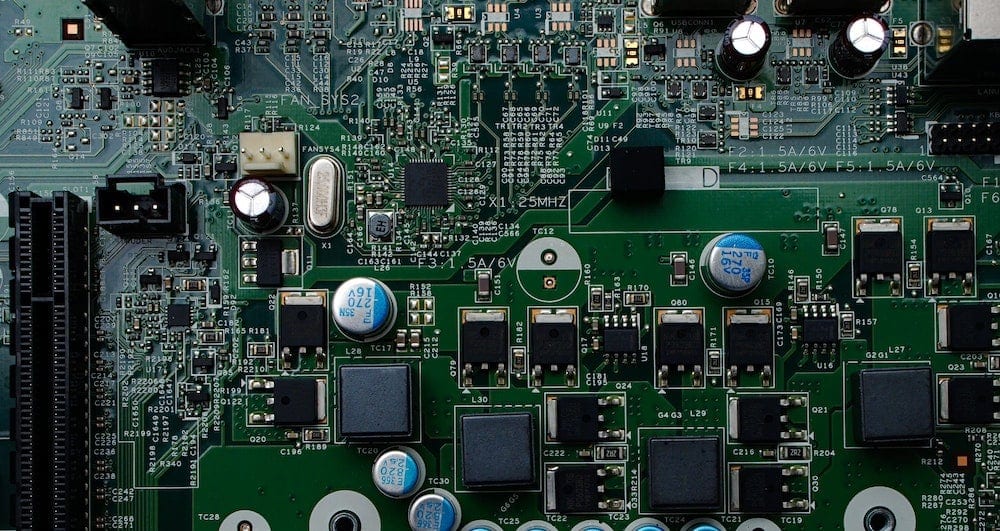

2. Increasing Importance of Cybersecurity

Following behind trend number 1 above, as manufacturers increasingly rely on digital systems, the importance of cybersecurity for every employee will increase. Every digital system will become a security vector and hacked factories stand to lose millions of dollars. Cybersecurity will be a major concern for manufacturers who will need to hire outside and help and train their staff members

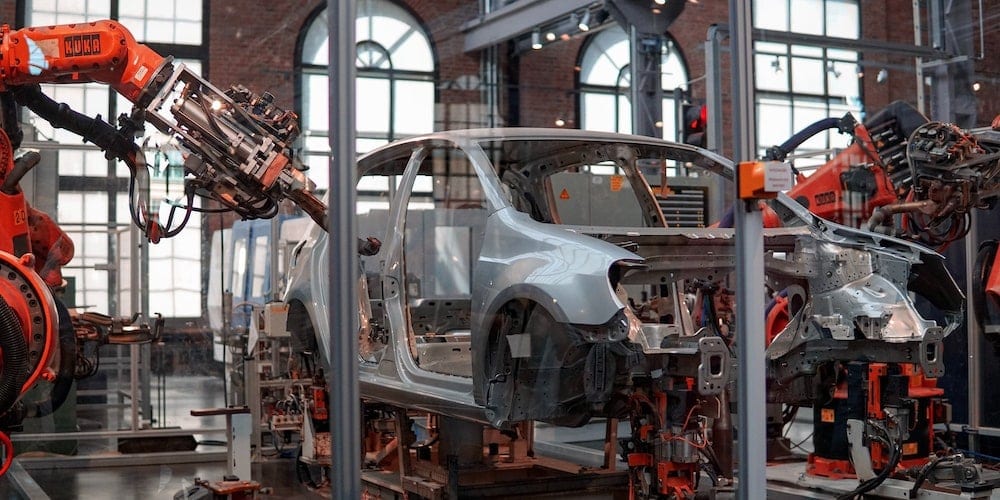

3. More Mobile Robots

From Industry Week: “Ecommerce leviathans like Amazon and Alibaba aren’t the only ones to have autonomous bots moving materials. With a full field of options, such as Fetch Robotics Freight 1500, many manufacturers and warehouses have found an affordable option for their application.”

Robots will begin to replace forklift drivers and other plant and warehouse employees. This will bring cost and safety benefits to some manufacturers and emphasizes the importance of continuous education for staff.

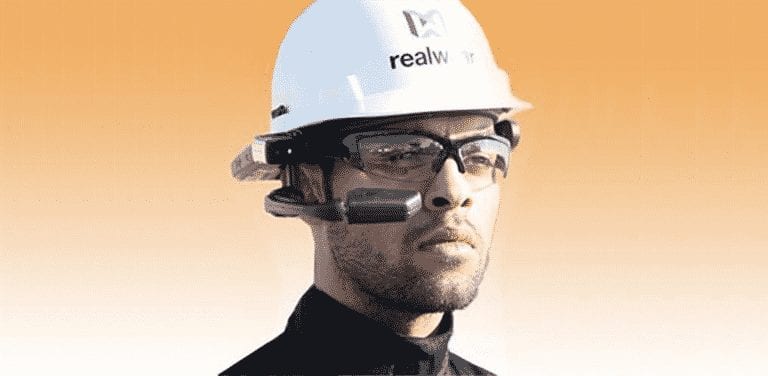

4. Wearable Technology

Manufacturing plants are predicted to increasingly leverage the power of wearable technologies to enhance the abilities of manufacturing floor staff. Devices such as smart eye-wear, fitness trackers, and other sensor-enabled wearables will become more common in the factory.

This technology can help with data collection, tracking, analytics, health-monitoring, safety, remote management, operational efficiency, communication, security, authentication, and more.

5. Further transition to renewable energy sources

From Deloitte: “The renewable energy transition appears poised to accelerate in the United States, with a growing list of states, cities, private and public sector organizations taking the lead.” Deloitte’s research shows that “64 percent of manufacturers surveyed plan to source a significant percentage of their electricity from renewable resources over the next five years.”

As for the motivations behind these plans to go renewable, “organizational transitions to renewable energy are being driven by cost-cutting (36.4%) and reducing environmental impact/carbon footprint (35.4%), according to survey respondents.”

Manufacturing Trends Post COVID-19

1. Supply Chain Disruption

A recent survey from the National Association of Manufacturers (NAM) showed that over 35% of manufacturers are facing supply chain disruptions as a result of COVID-19. We expect this number to be higher over time. As borders close and as countries respond to the global pandemic, manufacturers in the U.S. must re-examine supply chains for immediate solutions and long-term improvements in resilience and redundancy.

2. Reduced/Increased Demand

It is unclear how quickly economies will recover from the economic collapse caused by global quarantines. But it seems safer to say that consumer demand has dropped globally and will take some time to recover. Manufacturers face many challenges as a result.

On the other hand, certain manufacturers actually face the challenge of increased demand with toilet paper factories and grocery stores being the primary examples.

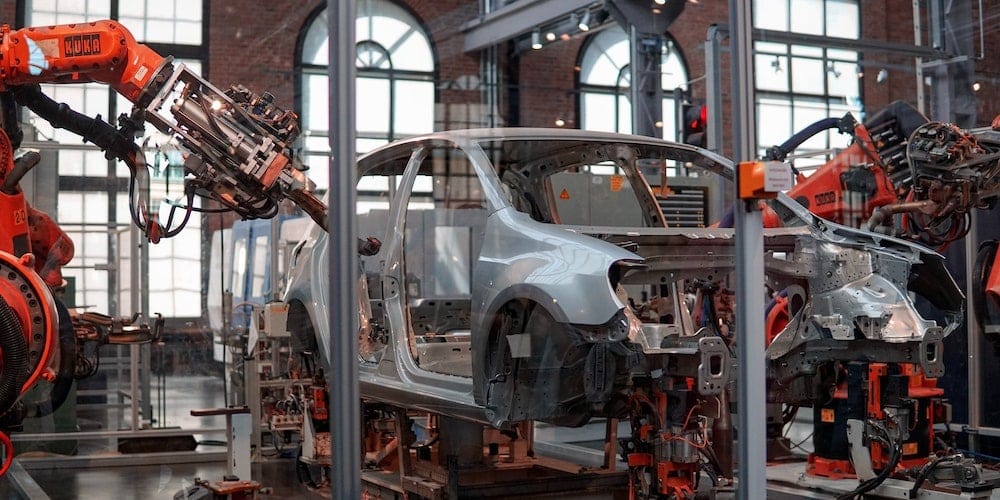

3. Adaptive Retooling

Whether it be perfume makers pivoting to hand sanitizer, guitar companies making face shields, or auto/airline/many other companies making ventilators and masks, it seems representatives from every industry are pitching in to help battle the Coronavirus and support medical staff on the front lines.

We at DMS specialize in creating custom solutions to solve your manufacturing challenges. We encourage you to bring your manufacturing challenges to us to see how we might be able to help. Our custom approach also allows for the rapid retooling of our machines so we can continue to solve your manufacturing challenges for years to come! Contact us now.