The DMS Blog

A New CNC Machine? In This Economy?

It’s a challenging time to consider a big investment. With rising interest rates and the highest interest rates since 2001, fewer people are willing to risk investing in big purchases like a house or car—or a new CNC machine. Today’s interest rates increase the cost...

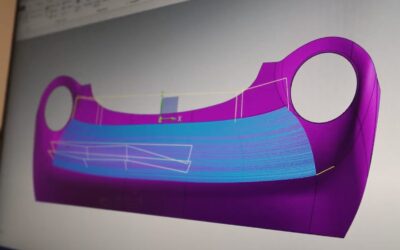

This Custom Router Is about to Leave Our Factory Floor

At Diversified Machine Systems (DMS) we make CNC machines with you in mind. Our lineup of American-made routers is designed to serve a broad range of manufacturing needs, from aerospace to automotive to the defense industry. But our favorite projects begin when a...

Restoring Classic Cars with New Technology

https://youtu.be/HUjmRh8Armw When DMS Solution Architect Jesus Molina was asked to work on a Porsche 914, he knew he had a special project on his hands. The Porsche 914 was originally developed as a collaboration between Porsche and Volkswagen in 1970. Envisioned as a...

Why the Automotive Industry Relies on CNC Machines

If you ever drive around town with a kid in the passenger seat, chances are you’ll quickly be reminded how unique each vehicle you pass is. That reminder can come with a punch to the shoulder (“Slug bug blue!”) or a gasp (“Check out that lambo!”). We may take our...

Fagor’s New Automation System Is Its Most Powerful Yet

At Diversified Machine Systems (DMS), we know that the quality of our machines depends on the quality of each unique part. That’s why our routers feature stress-relieved steel frames and American-made parts. It’s why we use Hiteco spindles and why we source our raw...

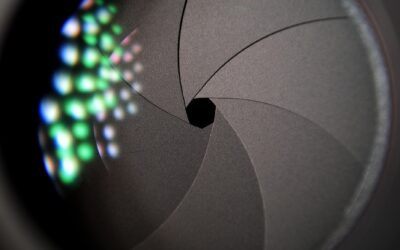

The New DMS Vision System Dials In Your Machining

When it comes to CNC machining, precision is of the highest priority. No matter what material you’re working with or what program you’re running, you want a machine you can count on for the highest degree of accuracy and repeatability. And you want all this—without...

5 Tips to Extend Your CNC’s Lifetime

Even a great car will begin to wear down over time, and a great CNC router is no different. But just as a good car owner can get more miles out of their car by keeping up with routine maintenance, a good CNC operator can extend their machine’s lifetime if they take...

Your New Favorite CNC Shop

You know your favorite hardware store? The one where it’s always easy to find what you’re looking for. The one with customer service that shows up when you need them, but stays out of your way when you don’t. The one that is stocked with everything you need—even that...

The DMS 3-Axis Lineup

Diversified Machine Systems (DMS) has spent decades building a catalogue of 3-axis CNC machines that we can proudly offer to manufacturers in every industry. It all starts with a solid foundation—a rigid or stress-relieved steel frame, large bridge, and Fagor...