Orthotics

DMS works with orthotics customers to create custom end-user products that can change people’s lives. We work with our users to ensure their products and devices are a perfect fit every time.

Serving the Orthotics Industry for 30 Years

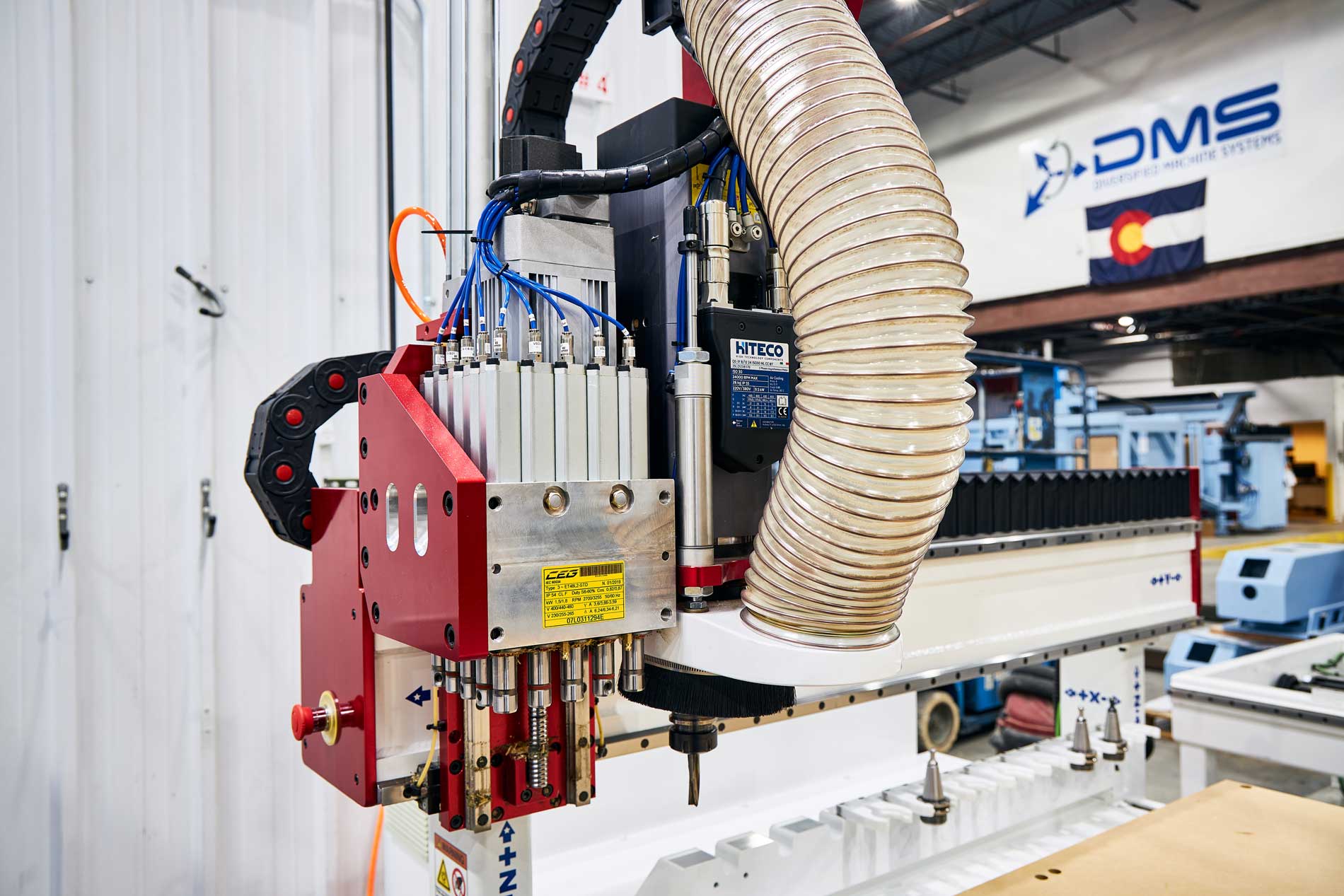

At Diversified Machine Systems (DMS) many of our clients come to us with a need for a machine that can cut orthotics. In fact, this is one of the top industries that we serve and configure machines for. For orthotics, our customers choose from our Freedom line sizes to create the medical products that their patients need to help with their healing and lifestyle changes.

We Speak Your Language

If you specialize in orthotics production, we will team you up with a salesperson who understands the field, and will consider all the facets of your manufacturing pipeline to make a machine that will fit your needs. We will first understand which pieces you’re trying to cut, and which materials you’ll be using. Oftentimes, our customers will use thermoplastics, polypropylene, and EVA foam for their orthotics needs.

The Freedom Line

For orthotics, we usually recommend a machine from our Freedom line. This means our customers get all the science and engineering backed by our DMS experts at the value of our specialized 3-axis line. Our sales team is specially trained to understand orthotics customers specifically, and recommend a Freedom machine that will help them reach their manufacturing goals. Oftentimes, our customers will get a Freedom 4’x’4, or 4’x8’ installed to get their manufacturing up and running.

Reviewing Your Options

Oftentimes, to solve their complex cutting needs, a sales person will recommend a multiple tool change setting to make sure they are using their Freedom DMS machine to its fullest capability. Additionally, a DMS sales rep will walk you through your software options, and use their experience with past orthotics customers to make a recommendation that will suit your manufacturing needs best.

Quality That Matters

Even though we know each orthotic piece needs to be cut precisely, when it comes to CNC configuration, it is by no means one size fits all. We will work with you to create the machine that will get you the end result you need in a size your factory can handle. We work closely with our customers to make sure they’re satisfied from blueprint to factory floor installation.

With an ever changing landscape with development and research, we understand that the orthotics industry is frequently evolving to adapt to human needs. Our constant updates and innovations ensure that you are getting top of the line technology engineered with the highest quality and care.

DMS and the Orthotics Industry

As an Original Equipment Manufacturer, (OEM) DMS is able to build custom machines for various materials and applications for orthotics. Our in-house engineers understand the unique challenges that come with the orthotics industry, and are specially trained to help professionals in this field solve specific problems.

When it comes to the orthotics field, DMS is a proven expert partner for companies around the globe. Our team of specialists will work with you to get a CNC router in your shop that can produce the specific results that you’re looking for with your new machine.

If you would like to discuss more on how our USA-based team of experts can build you the perfect CNC router for your orthotics manufacturing needs reach out to us today at 855-266-5064 or email us at info@dmscncrouters.com.