Mold and Pattern Making

DMS is an expert at helping our mold and pattern making partners create casts and designs. Our machines have the accuracy and rigidity to get the results our partners need every time.

Serving the Mold and Pattern Making Industry for 30 Years

Many customers at Diversified Machine Systems (DMS) use their 3 and 5-axis CNC routers to cut molds and patterns to create a myriad of items and project pieces. Mold and pattern makers use 3D laser scanners, advanced recognition software, and state of the art CNC machining centers to create architectural details, corporate logos, prototypes, sculptures, and mannequins for a wide variety of industries.

Various Applications

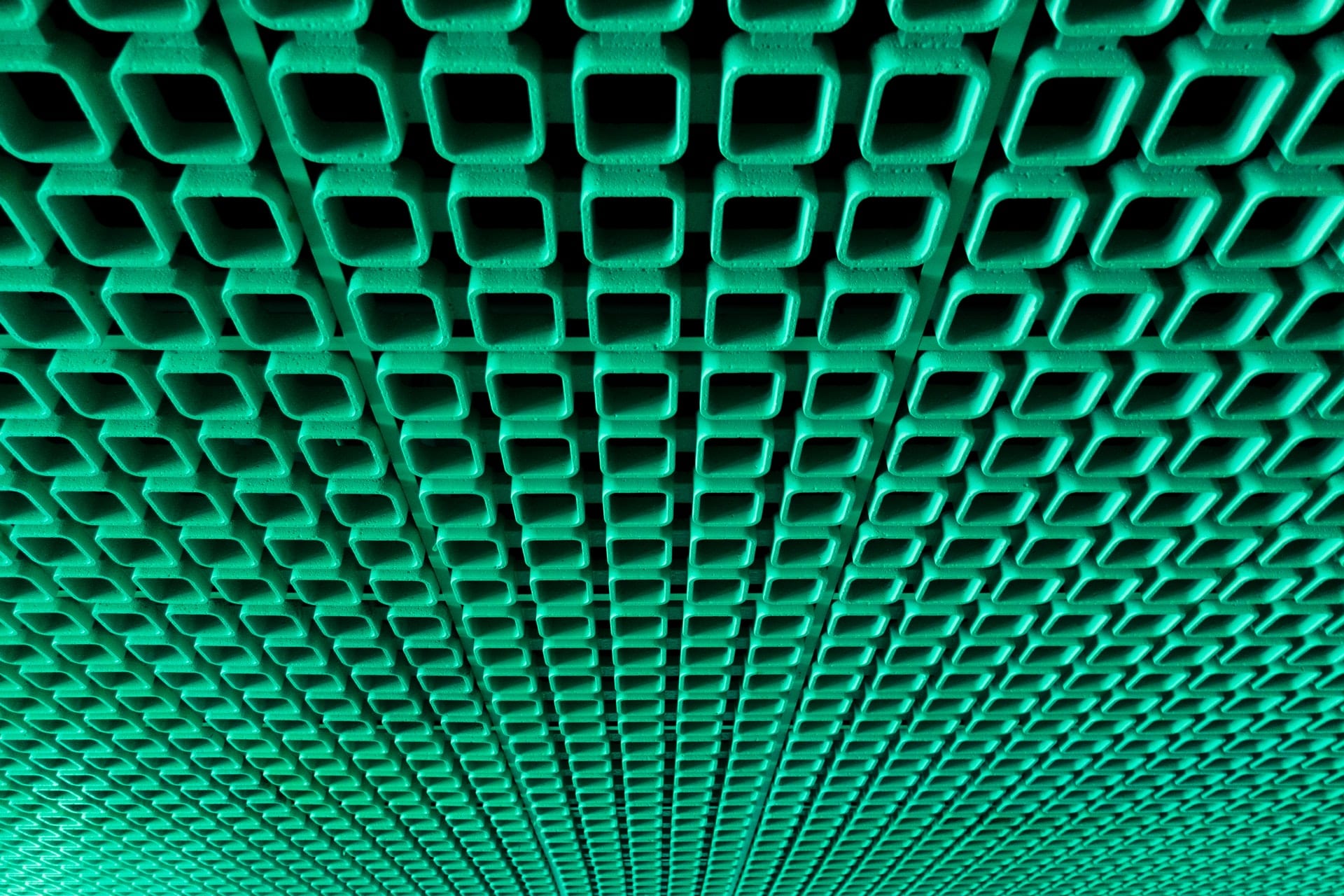

DMS 3 Axis and 5-axis CNC routers are used extensively in the mold and pattern industry to transform digital information into finished products typically made out of wood, MDF and foam. Our routers are also employed to produce prototypes for the automobile, movie and construction industries. Speed and accuracy are of the utmost importance in mold and pattern making, and DMS’ reputation for repeatability makes them an ideal choice for this application.

Common Materials

The most common materials to cut molds on are EVA foam and plastics. These lightweight yet durable materials allow for makers to create molds that are used across a myriad of sectors and industries. Since mold and pattern making touches so many industries, we configure custom machines that can create the mold and patterns that you need for your industry.

Configuring Your Machine

To decide which machine is best for your needs, a representative from DMS will fully try to understand the part you’re cutting from the inside out. They will ask you about your production schedule, your factory space and suggest the right software for your needs. At DMS, we understand that not every CNC fits every production need. So we will work with you to create an asset that will best serve everyone from your factory floor to your end users.

DMS and Mold and Pattern Making

As an Original Equipment Manufacturer, (OEM) DMS is able to configure custom machines for the unique needs of mold and pattern makers. Our in-house engineers understand the unique challenges that come with manufacturing mold and patterns and are specially trained to help professionals in this field solve complex problems.

We understand that the mold and pattern landscape is ever-changing, technical and intricate. The engineers at DMS speak the military language and spin up innovative ideas that have never been seen before. Our goal is to meet your mold and pattern manufacturing needs in a way that not only saves you time but reduces waste and overhead costs. Many of our partners come to us with a part in mind, and from there we create a CNC router with the capabilities that they need from blueprint to factory floor installation.

When it comes to mold and pattern making manufacturing, DMS is a proven expert partner for companies around the globe. Our team of specialists will get a machine in your shop that can produce the specific results that you’re looking for with your CNC router or machining center.

If you would like to discuss more on how our USA-based team of experts can build you the perfect CNC router for your mold and pattern making manufacturing needs reach out to us today at 855-266-5064 or email us at info@dmscncrouters.com.