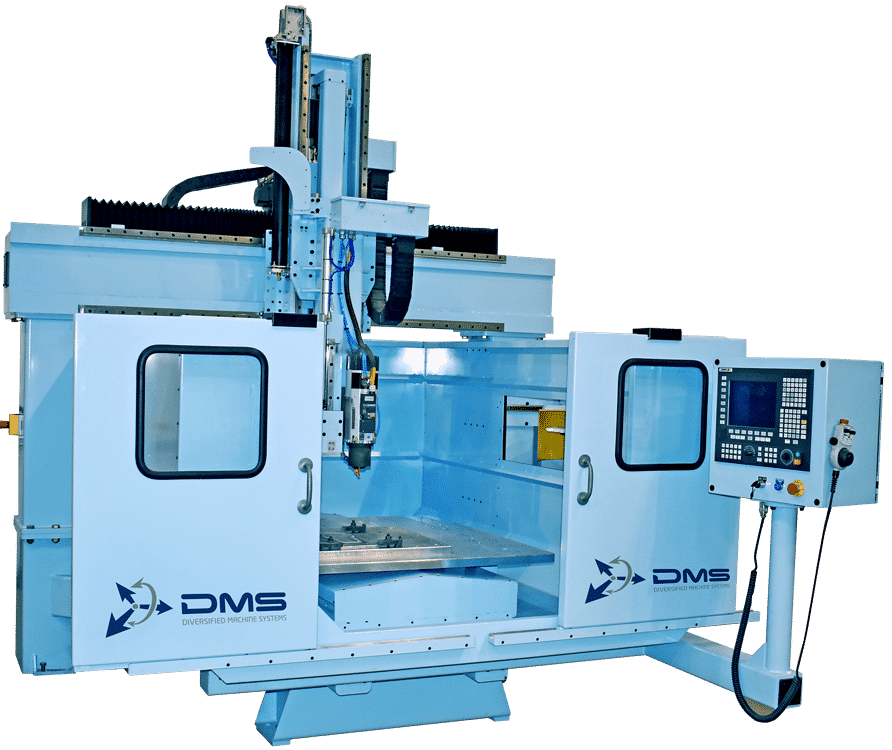

The Hybrid Line

Subtractive manufacturing meets additive. The same industrial components demanded by Fortune 500 companies are standard on all Hybrid machining centers, which translates into a durable product that your business can depend on.

Our Hybrid machining centers are produced in Colorado Springs, CO where we handle everything from welding the frame together to assembling the various components and finally conducting quality control cuts.

Every Hybrid machining center comes with lifetime technical support. Contact us with your production goals and we will design a machine to fit your floor space and exceed your goals.

Ideal For

This unique 3-axis combination additive / subtractive machining center is ideally suited for machining aluminum materials, process development, and material characterization.

Common Materials

Aluminum

Common Industries

Defense – Military – Aerospace – Automotive – Mold & Pattern Making

Average Build Time

14-16 weeks

Starting Price

$264,700

Base Features

- Hybrid Machine Operations

- True 3D Free Space Additive/Subtractive

- Low Cost Feedstock

- Inter-pass Machining Maintains Tolerance & Quality

- Fagor 8065 4-axis industrial controller with 10.4″ high resolution color monitor

- Integrated Fronius CMT Advanced GMAW welding system.

- 1” Phenolic Table machined flat with steel inserts on 6″ centers

- Recirculating ball screw assembly on all axes

- Electro spindle HSD 12 hp / 9 kW Standard (other hp options available)

Specs

- 2’ x 2’ x 2’

- Additive Capability – Integrated Fronius CMT Advanced GMAW welding system

- Fast Deposition, 3-5 lb/hr

- Inert Environment not Required

- Rapid Feed Rate – up to 1800 inches per minute

- Rotational Speeds – up to 8000 degrees per minute

- X Axis Stroke – 24” / 610 mm

- Y Axis Stroke – 24” / 610 mm

- Z Axis Stroke – 24” / 610 mm

- Servo & Drive System – Fagor closed-loop brushless AC servo motors and servo amplifiers on all axes

- Power Requirement – CNC reqts: 380-480V, 3-phase, 60 Amps

- Air Requirements – 5 CFM at 95 PSI

- Lubrication – manual

Customizations

- Welding Fume Management system

- Table options

- Table accessory options

- Probe options

- Software

Support

- Software Options Support

- Complimentary Technical Support

- Professional installation & training available

- Warranty – 1 Year limited warranty and basic phone support

- Parts Warranty

Ideal For

This unique combination additive/subtractive machining center is ideally suited for process development and mold making.

Common Materials

Polymer – Composites

Common Industries

Defense – Military – Aerospace – Automotive – Mold & Pattern Making

Average Build Time

16-18 weeks

Starting Price

$928,000

Base Features

- Hybrid Machine Operations

- Large Range of Printable Materials

- Large Scale 5’x10’x4’

- Fagor 8065 5-axis industrial controller with 21″ touch screen monitor

- Ethernet TCP/IP, USB & Serial Port Connections

- Servo and Drive Systems – Fagor closed-loop brushless AC servo motors and servo amplifiers on all axes

- 5′ x 10′ 1” Aluminum Table with 8-zone vacuum table and 1/2″ inserts

- Electro Spindle – HSD 16 hp / 12 kW Standard (other hp options available)

Specs

- Rapid Feed Rate – up to 1500 inches per minute

- Rotational Speeds – up to 8000 degrees per minute

- Fast Deposition, up to 150 lb/hr

- X Axis Stroke – 60” / 1524 mm

- Y Axis Stroke – 120” / 3048 mm

- Z Axis Stroke – 48” / 1219 mm

- X & Z Axis Drive – Recirculating ball screw assembly

- Y Axis Drive – Helical rack and pinion

- Independent Z Axis – Independent Z axis for polymer extruder

- Servo & Drive System – Fagor closed-loop brushless AC servo motors and servo amplifiers on all axes

- Additive Feeder – Dri-Air hopper feeder and dryer for polymer feedstock

- Additive Extruder – 30mm pellet-fed extruder, with three heater zones

- Air Requirements – 5 CFM at 95 PSI

- Lubrication – manual

Customizations

- Custom Table Sizes

- Automatic Tool Changer

- Tooling Packages

- Tool Height Sensor

- Probes

- Pendant options

Support

- Software Options Support

- Complimentary Technical Support

- Professional installation & training available

- Warranty – 1 Year limited warranty and basic phone support

- Parts Warranty

Ideal For

This unique 5-Axis combination additive / subtractive machining center is ideally suited for machining aluminum materials, process development, and material characterization.

Common Materials

Aluminum

Common Industries

Defense – Military – Aerospace – Automotive – Mold & Pattern Making

Average Build Time

14-16 weeks

Starting Price

$560,000

Base Features

- Fagor 8065 5-axis industrial controller with 21″ touch screen monitor

- Hybrid Machine Operations

- Additive Capability – Integrated Fronius CMT Advanced GMAW welding system

- Inter-pass Machining Maintains

Tolerance & Quality - Inert Environment not Required

- Large Scale 5’x10’x4’

- True 3D Free Space Additive/Subtractive

- Low Cost Feedstock

- Ethernet TCP/IP, USB & Serial Port Connections

- Servo and Drive Systems – Fagor closed-loop brushless AC servo motors and servo amplifiers on all axes

- 1” Phenolic Table machined flat with steel inserts on 12″ centers

- Electro Spindle – HSD 16 hp / 12 kW Standard (other hp options available)

Specs

- Rapid Feed Rate – up to 1500 inches per minute

- Rotational Speeds – up to 8000 degrees per minute

- Fast Deposition, 3-5 lb/hr

- X Axis Stroke – 60” / 1524 mm

- Y Axis Stroke – 60” / 1524 mm

- Z Axis Stroke – 48” / 1219 mm

- X & Z Axis Drive – Recirculating ball screw assembly

- Y Axis Drive – Helical rack and pinion

- Independent Z Axis – Independent Z axis for metal extruder

- Servo & Drive System – Fagor closed-loop brushless AC servo motors and servo amplifiers on all axes

- Power Requirement – CNC reqts: 380-480V, 3-phase, 60 Amps

- Air Requirements – 5 CFM at 95 PSI

- Lubrication – manual

Customizations

- Welding Fume Management system

- Table options

- Table accessory options

- Probe options

- Software

Support

- Complimentary Technical Support

- Professional installation & training available

- Warranty – 1 Year limited warranty and basic phone support

- Parts Warranty