Diversified Machine Systems (DMS) is proud to announce the next generation of CNC machines in the Klondike Series. For this machine we pulled out all the stops, manufacturing a router with four uniquely operating spindles, increased feed rates, and reduced cycle times. All of this is a big step forward in the evolution of CNC routers—but it would be incomplete without a new and improved user interface.

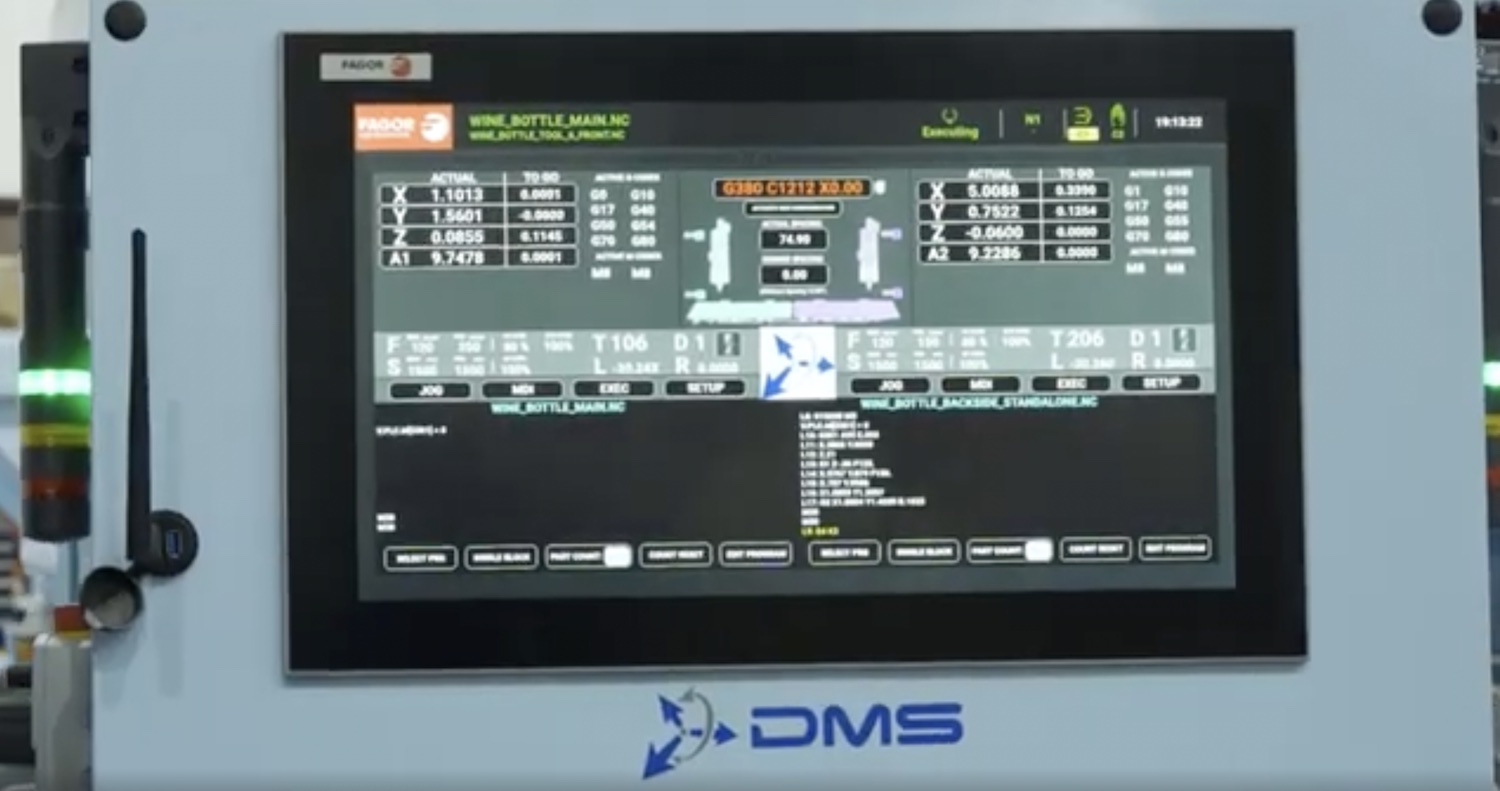

For the Klondike Series, DMS is once again partnering with Fagor to offer a router that features their best automation system to-date. This is a big improvement on your average user interface—innovative, intuitive, and user-friendly.

Next Gen Fagor Tech

On our state-of-the-art Klondike series, we’re rolling out the new Fagor Quercus automation system. Fagor is a longtime partner with DMS, and we’re thrilled with the ways they’ve expanded their tried-and-true systems with a brilliant redesign.

Quercus is powerful, compact, and smart. It features improved control algorithms, redesigned servo drives and power supplies, more memory capacity, and the latest servo bus—while somehow managing to be roughly twice as compact as previous models. Quercus meets all current market requirements, while also allowing for the integration of future add-ons. This ensures that the Klondike is adaptable to whatever the future brings.

Fagor offers several models for their new system, and we went with the clear winner. For a machine with four unique spindles, the Fagor 8065 Power HMI Elite is the perfect fit. This model features improved integration of functions for multiple axes. It includes the new Sercos III Servo Bus, which uses industrial ethernet technology at 100 MBd.

Quercus is the CNC automation system that helps you grow vertically and allows you to be prepared for the most demanding requirements of current and future markets.

Easy Reconfiguring

Manufacturing these days requires a high degree of flexibility. That’s why we built the Klondike series with a user interface that is easy to reconfigure, depending on each day’s unique needs. The Klondike’s four spindles can function as one machine or be programmed to act as two, three, or even four independent machines simultaneously. The intuitive user interface allows the operator to take full advantage of these possibilities, even with minimal programming knowledge.

Intuitive UI

A great machinist shouldn’t have to be a great programmer to get the job done. With our new and improved UI, it’s unnecessary to memorize high-level syntax and g codes. The Klondike is programmed to talk to the operator through an accessible user interface—without requiring a familiarity with complex code. This lets CNC operators run all operations in as few button presses as possible.

The intuitive UI allows a new machine operator to learn the ropes quickly, even if they’re new to the Klondike or to routers in general. Our goal with this machine was to offer a UI that was so intuitive that a new operator could get up-to-speed in a single day. Of course, this is great news for employers and floor leads, who can equip their staff without a huge dip in production.

DMS is excited to offer the Klondike series as the latest evolution in CNC technology. We believe that easy reconfiguring and an intuitive UI make your job easier and lead directly to increased productivity. We’ve worked hard to manufacture the best product possible, so that you can do the same.