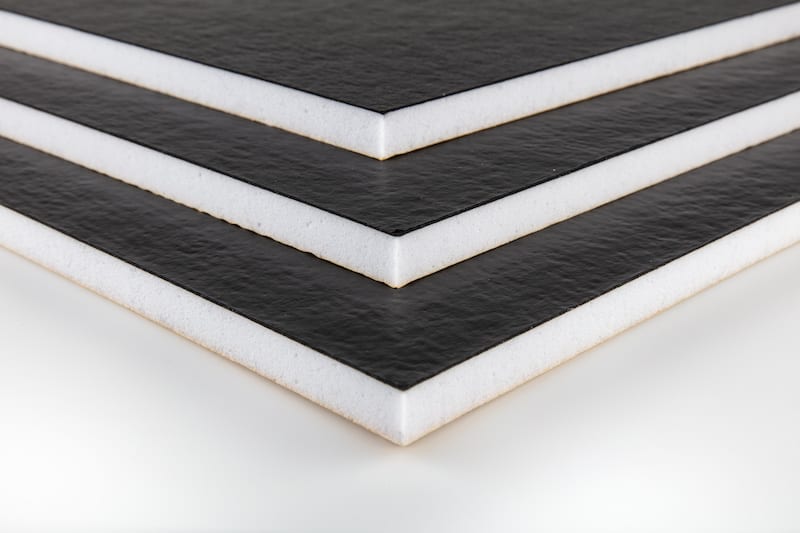

Foam Materials

Foams are used in a wide variety of industries including aerospace, packaging, movies, sporting goods, automotive, and furniture manufacturing.

Machining Foam Materials with DMS CNC Routers

Foam is a popular choice for producing molds, models and prototypes, because it’s inexpensive and readily available. Utilizing foam in this capacity gives machinists and technicians the freedom to experiment with multiple layouts and options, without worrying about expense. Foam materials are most commonly seen being used in the mould and pattern industry. However, machining foam can be difficult due to the material itself, which is lightweight and non-heat resistant. These issues, combined with the often complex nature of the 3-D foam shapes being produced, necessitate an advanced, high-performance cutting and shaping solution.

DMS 3 and 5 axis moving gantry machining centers are ideal for cutting and shaping foam in a variety of industrial and manufacturing applications. DMS machines feature many options which make them the ideal choice for foam manufacturing applications. They include:

- Enclosed Machine Format or Open Machine Format

- Single Shuttle Table or Twin Shuttle Tables

- Mechanical Hold Down or Vacuum Hold Down

- Many Z Height Options

- Manual Doors or Automatic Doors

DMS 3 and 5 axis machining centers are fully customizable to your unique specifications and parameters – we make the complex simple and your business more productive. At Diversified Machine Systems, our objectives are your objectives. Our experienced team of engineers, designers and account managers will work with you every step of the way to help you meet your production goals.