5-Axis CNC Machines

Named after American National Parks, our CNC routers are strong, long-lasting and always made in the USA.DMS 5-Axis CNC Routers

DMS 5-axis CNC routers offer a universal platform ideal for configurability for a myriad of applications. Our machines feature a large bridge, rails and ball screw which, when combined with a heavier gauge, all-steel frame, results in a machine that is rugged, durable and ideal for high production factories.

Looking for something custom? Our engineers have over 70 years of combined CNC experience with a proven track record of designing custom CNC solutions. Contact us with your production goals and we will design a machine to fit your floor space and exceed your goals.

Denali5

This 5-axis CNC router is a perfect mid-range “Trim Center” style machine that can be used to process a wide range of applications, from light materials such as wood and foam to composites and ferrous and non-ferrous metals. This machining center is the ideal choice for companies looking for a high-precision 5-axis CNC router without a large footprint. The 5-axis overhead gantry will help you expand your production capabilities with its efficient, compact design, ideal for dust containment, and its exclusive quick-change fixture system.

Everglade5

This 5-axis CNC router is a continuous -use, medium to heavy duty machine that can be used to process a large variety of applications from light materials and foam to composites to ferrous and non -ferrous metals. This machine series is available in a range of sizes and styles to accommodate various production needs. These high -precision machines are commonly used for shaping and drilling processes. All models have 36” of Z and Fagor controllers.

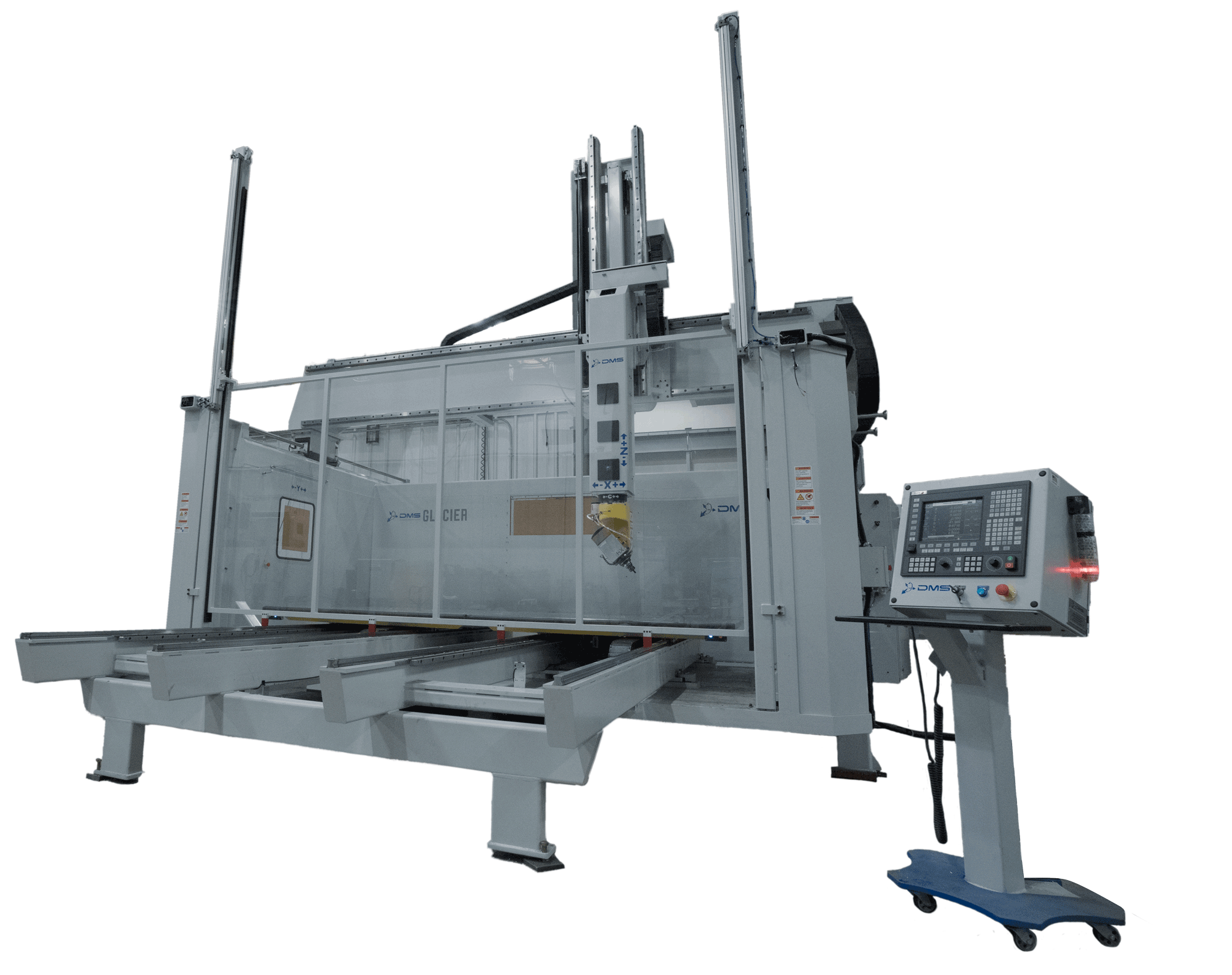

Glacier5

Explore the pinnacle of manufacturing innovation with the Glacier5, our advanced 5-axis CNC machine. Designed with a fully enclosed architecture for those who demand precision and versatility, Glacier5 revolutionizes the way you work with a wide array of materials and material presentation options. From intricate aerospace components to complex automotive parts, this machine offers unmatched accuracy, speed, and adaptability. Tailored solutions and expert support ensure that your manufacturing needs are met with the highest standards. Elevate your production capabilities and achieve excellence with Glacier5.

Mammoth5

This CNC router is a continuous-use, feature-rich, heavy-duty machining center designed to process a wide variety of applications, from light materials such as wood and foam to composites and ferrous and non-ferrous metals. This machining center has the option of sliding doors on both the front and back, allowing for easy loading/unloading of large materials. The universal fixture table improves productivity by reducing downtime between part runs.

Redwood5

Discover unparalleled precision with DMS’s Redwood5, the 5-Axis CNC Machine designed for excellence. Engineered for diverse material processing needs across industries, Redwood combines high-speed performance with unmatched accuracy. Its robust open architecture design ensures durability for continuous operation, while flexible customization options cater to your specific production needs. Experience the confidence of investing in technology that grows with you, backed by comprehensive support and warranty services. Elevate your manufacturing capabilities with Redwood5.

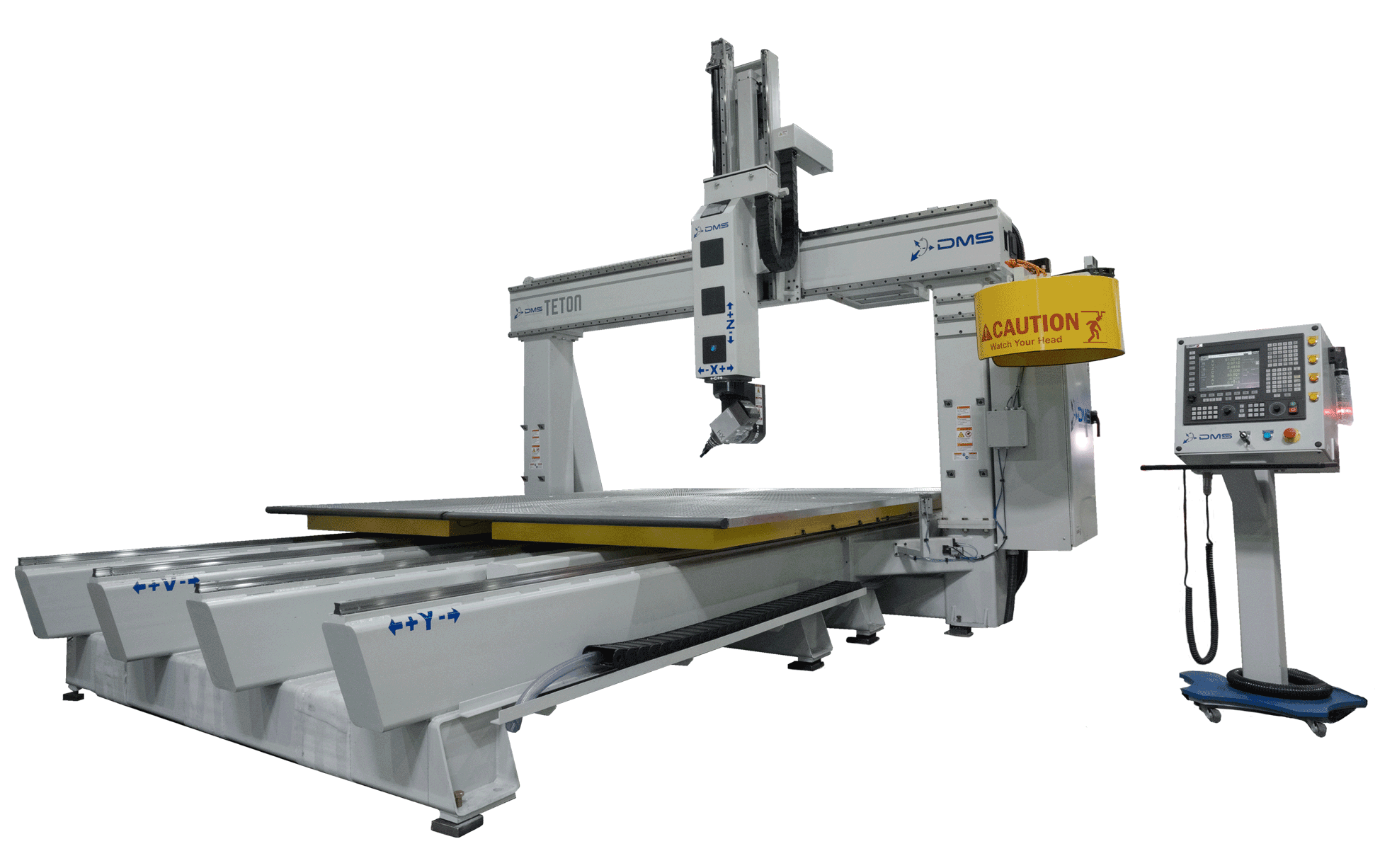

Teton5

The Teton5, with its advanced 5-axis CNC capabilities, now boasts enhanced efficiency through pendulum processing, allowing for continuous operation and minimized downtime. This feature is perfect for high-volume production environments where maximizing machine utilization is key. The fixed gantry offers unmatched rigidity in High-Z applications which ensures that the Teton5 remains at the forefront of precision and flexibility, catering to industries that demand the highest standards of accuracy and efficiency.

Yellowstone5

This 5 -Axis Large Format U -frame Gantry CNC Machine is a continuous -use, heavy duty machine that is feature rich, and can be used to process a wide variety of applications ranging from foam to aluminum. This machine can be manufactured with a universal fixture table, which can perform multiple tasks without requiring the user to stop production. The design of this machine allows for easy loading/unloading of large materials, as the front doors slide open and close. The universal fixture table gives your business the option to improve productivity by reducing downtime between part runs. This machine features an all -steel frame, which is stress relieved and welded in -house to ensure the highest quality. All models have 48” of Z and Fagor controllers.