Whatever Your CNC Needs, DMS Has a Machine For You

Every manufacturing business has unique needs. At DMS, we pride ourselves in being able to serve a wide variety of businesses ranging from small, 1-man woodworking shops to large aerospace corporations. DMS offer four product lines: DMS Essentials, DMS Custom, Freedom, and Hybrid. Take a look blow to find out more. As always, feel free to contact us directly if you need help in identifying the best machine for you.

DMS Machines

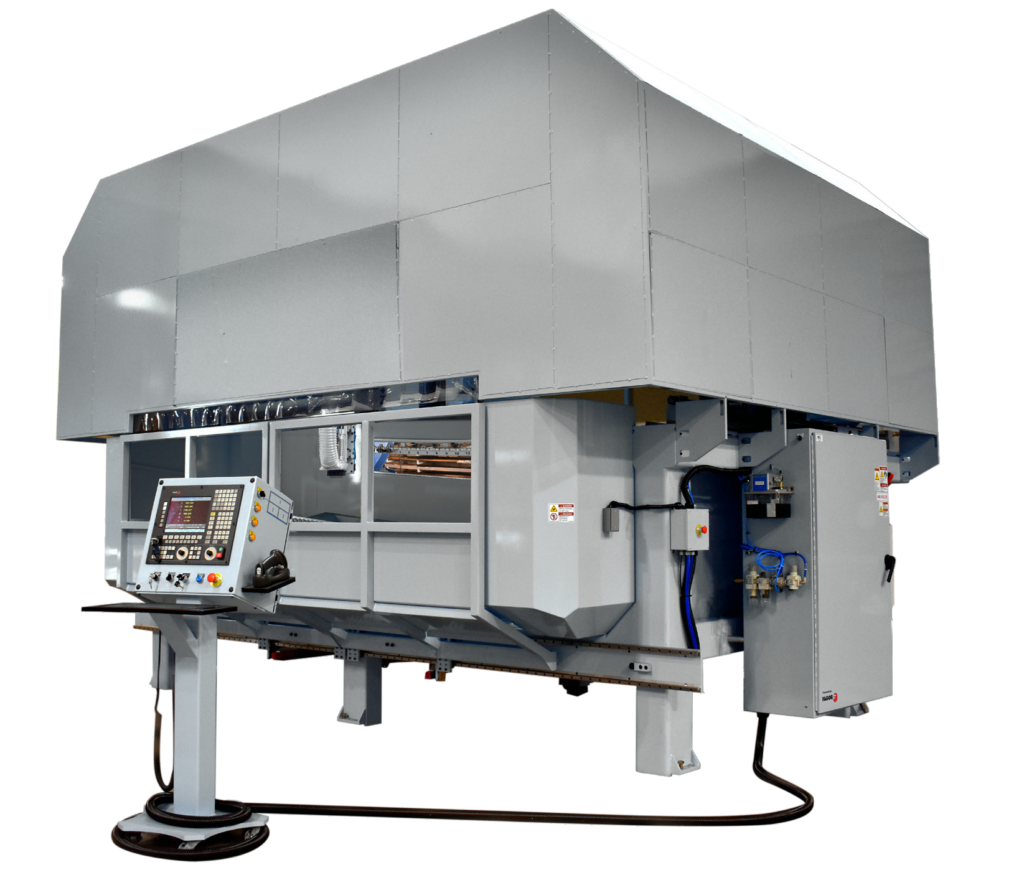

3 Axis CNC Routers

DMS CNC routers offer a universal platform ideal for configurability for a myriad of applications. Our machines feature a large bridge, rails and ball screw which, when combined with a heavier gauge, all-steel frame, results in a machine that is rugged, durable and ideal for high production factories.

A robust CNC with single or twin moving tables and multiple spindle options. The twin table setup enables pendulum processing, cutting on one station while loading the other. Built for rigidity on strokes up to 12′, it delivers reliable performance for demanding applications.

The Bryce3 combines the strengths of the Bryce and Redwood series in a versatile 3-axis CNC. Designed for precision across diverse materials, it offers strong performance, reliability, and ease of use. A cost-effective solution for businesses seeking quality and adaptability.

The Klondike twin moving table router runs with multi-channel and multi-spindle configurations. Operators can use it as 2, 3, or 4 machines, or pendulum process up to 4 spindles at once. Increased feed rates and acceleration improve throughput and reduce processing time.

An evolution of the Redwood series, Redwood3 brings 3-axis precision to a proven platform. Optimized for speed and accuracy, it balances performance with reliability. With customization and support options, Redwood3 delivers efficiency and precision across a wide range of materials.

The Glacier3 is a fully enclosed 3-axis CNC built on the strength of the Glacier series. It streamlines operations with reliable accuracy across varied materials. Offering customization and professional support, Glacier3 is a versatile solution for elevating production efficiency.

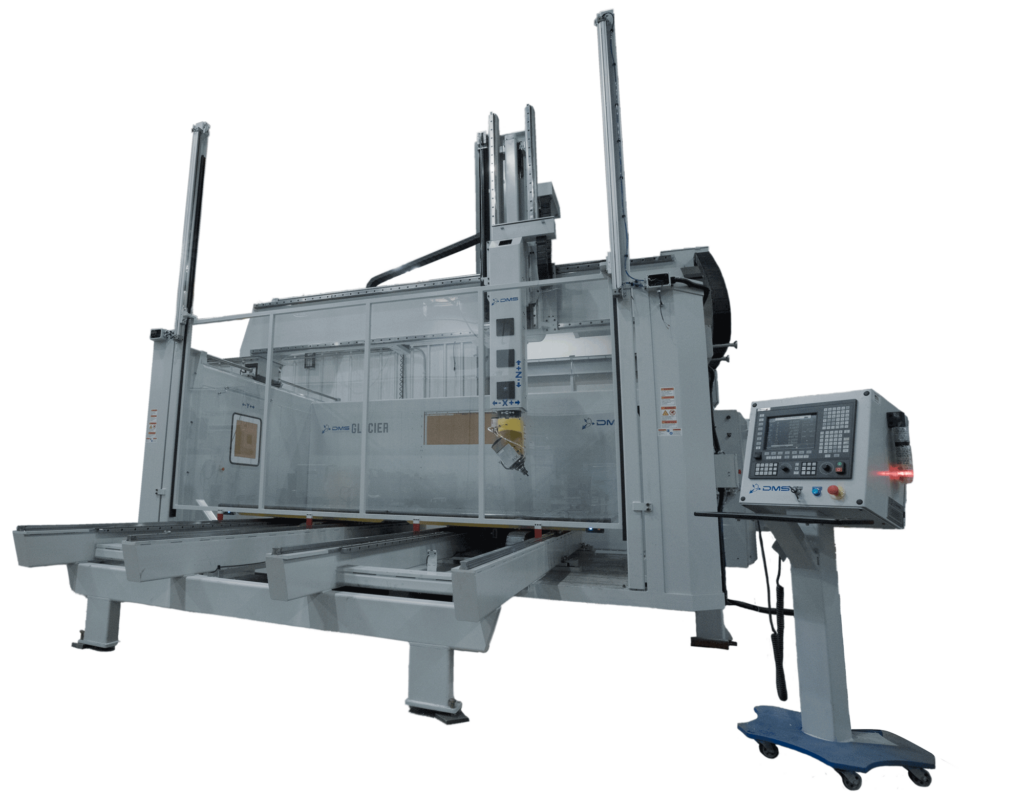

5 Axis CNC Routers

DMS 5-axis CNC routers offer a universal platform ideal for configurability for a myriad of applications. Our machines feature a large bridge, rails and ball screw which, when combined with a heavier gauge, all-steel frame, results in a machine that is rugged, durable and ideal for high production factories.

This 5-axis CNC router is a perfect mid-range “Trim Center” style machine that can be used to process a wide range of applications, from light materials such as wood and foam to composites and ferrous and non-ferrous metals. This machining center is the ideal choice for companies looking for a high-precision 5-axis CNC router without a large footprint. The 5-axis overhead gantry will help you expand your production capabilities with its efficient, compact design, ideal for dust containment, and its exclusive quick-change fixture system.

Explore the pinnacle of manufacturing innovation with the Glacier5, our advanced 5-axis CNC machine. Designed with a fully enclosed architecture for those who demand precision and versatility, Glacier5 revolutionizes the way you work with a wide array of materials and material presentation options. From intricate aerospace components to complex automotive parts, this machine offers unmatched accuracy, speed, and adaptability. Tailored solutions and expert support ensure that your manufacturing needs are met with the highest standards. Elevate your production capabilities and achieve excellence with Glacier5.

This CNC router is a continuous-use, feature-rich, heavy-duty machining center designed to process a wide variety of applications, from light materials such as wood and foam to composites and ferrous and non-ferrous metals. This machining center has the option of sliding doors on both the front and back, allowing for easy loading/unloading of large materials. The universal fixture table improves productivity by reducing downtime between part runs.

Discover unparalleled precision with DMS’s Redwood5, the 5-Axis CNC Machine designed for excellence. Engineered for diverse material processing needs across industries, Redwood combines high-speed performance with unmatched accuracy. Its robust open architecture design ensures durability for continuous operation, while flexible customization options cater to your specific production needs. Experience the confidence of investing in technology that grows with you, backed by comprehensive support and warranty services. Elevate your manufacturing capabilities with Redwood5.

The Teton5, with its advanced 5-axis CNC capabilities, now boasts enhanced efficiency through pendulum processing, allowing for continuous operation and minimized downtime. This feature is perfect for high-volume production environments where maximizing machine utilization is key. The fixed gantry offers unmatched rigidity in High-Z applications which ensures that the Teton5 remains at the forefront of precision and flexibility, catering to industries that demand the highest standards of accuracy and efficiency.

This 5 -Axis Large Format U -frame Gantry CNC Machine is a continuous -use, heavy duty machine that is feature rich, and can be used to process a wide variety of applications ranging from foam to aluminum. This machine can be manufactured with a universal fixture table, which can perform multiple tasks without requiring the user to stop production. The design of this machine allows for easy loading/unloading of large materials, as the front doors slide open and close. The universal fixture table gives your business the option to improve productivity by reducing downtime between part runs. This machine features an all -steel frame, which is stress relieved and welded in -house to ensure the highest quality. All models have 48” of Z and Fagor controllers.

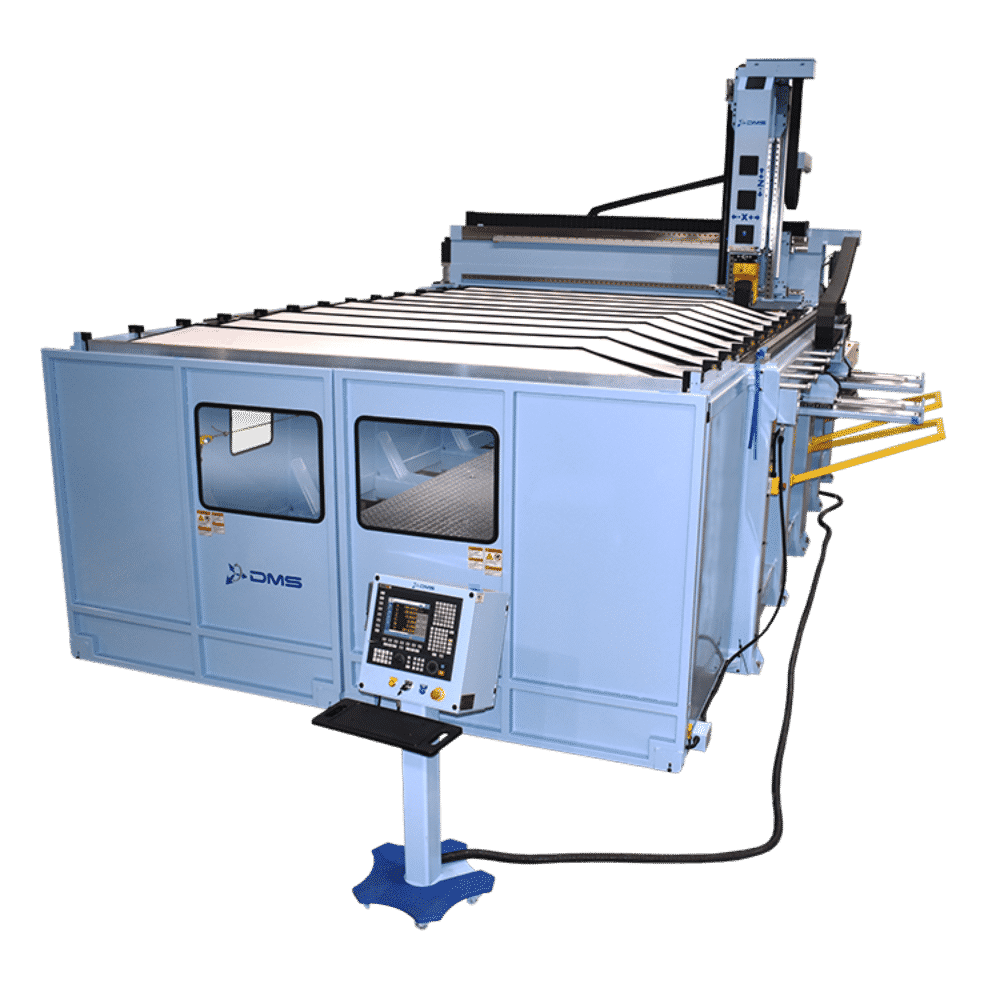

Freedom CNC Routers

Whatever material you are working with, we can configure and build a CNC router to accurately and efficiently get the job done. The same industrial components demanded by Fortune 500 companies are standard on all our Freedom machines, which translates into a durable product that your business can depend on.

The Freedom 4×4 CNC router brings high quality and durability to a small workspace. It is ideal for small, specialty manufacturing like Orthotics and for shops requiring a very small footprint like garage or home shops.

The Freedom 4×8 CNC router is a great entry-level, industrial machine or can be a fine addition to the advanced home workshop. It is ideal for processing 4×8 wood and plastic sheet material or composite panels and nested-based applications. Great for hardwood, thin aluminum sheet cutting and 3D pattern making or carving

The Freedom 10 Standard CNC Router is an upgrade from the Freedom 4 or 8 in strength and weight and provides a large work area ideal for nested-based machining.

The Freedom 12 CNC Router is an industrial-quality 3-axis 5′ x 12′ moving gantry CNC router with 12″ of Z-axis travel and is capable of maximum rapid feed rates of 1,200 inches per minute.

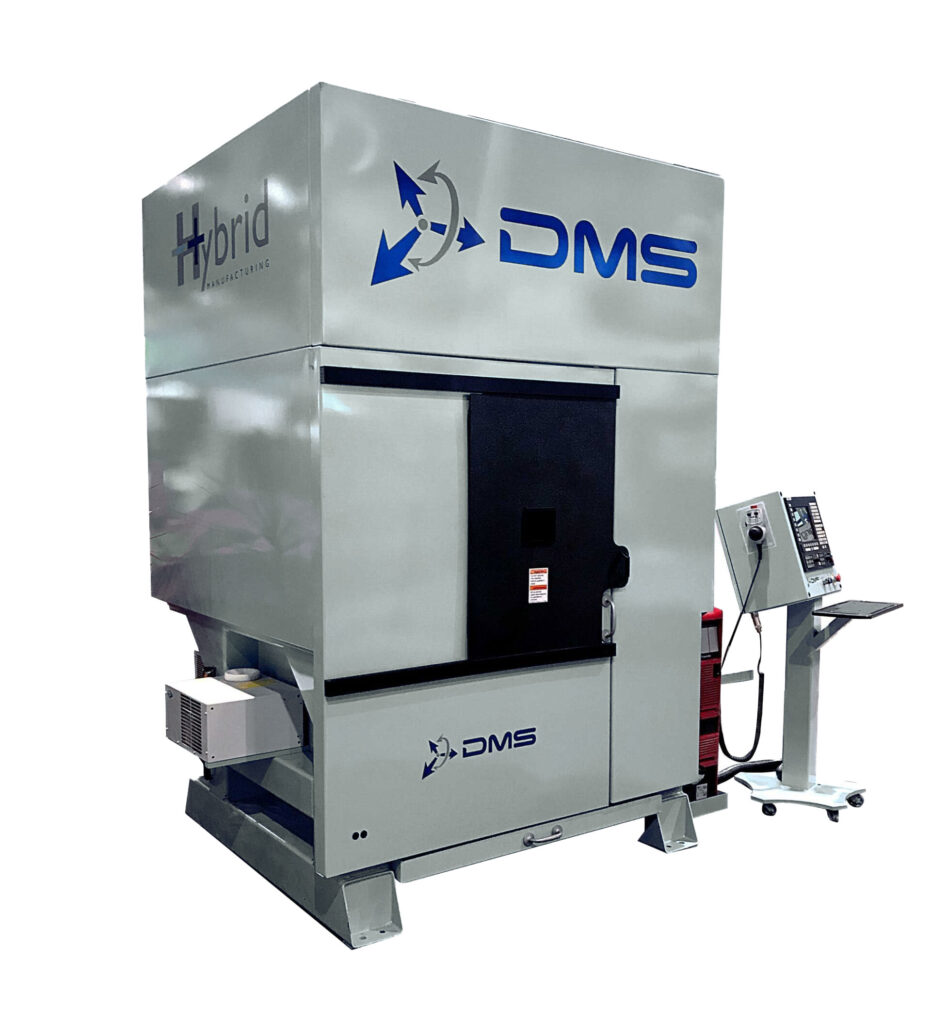

Hybrid CNC Routers

Subtractive manufacturing meets additive. The same industrial components demanded by Fortune 500 companies are standard on all Hybrid machining centers, which translates into a durable product that your business can depend on.

Our Hybrid Hero CNC is designed to be an entry-level machine for customers who are interested in our hybrid manufacturing processes. The machine has been designed to fit through a standard 74″x 81” double door, and does not require as much floor space to operate as our larger machines. It is equally suited for process development and research or production runs of small parts. The optional tilt rotate table adds 5-axis deposition and machining capabilities.

Our Hybrid Liberty machine series are 5-axis machines designed to expand our capabilities to include harder materials including various steel and stainless steel alloys. These machines all feature tilt rotate tables to increase the complexity and types of parts that can be produced. We offer two different machine sizes in this line, with a 600 or 1200mm diameter table.

The Klondike twin moving table router runs with multi-channel and multi-spindle configurations. Operators can use it as 2, 3, or 4 machines, or pendulum process up to 4 spindles at once. Increased feed rates and acceleration improve throughput and reduce processing time.

Need a custom machine?

Is your manufacturing setup unique? Our engineers have over 70 years of combined CNC experience with a proven track record of designing custom CNC solutions. Contact us with your production goals and we will design a machine to fit your floor space and exceed your goals.

Let’s Engineer a CNC Machine for Your Business.

Talk with our U.S.-based engineers about custom 3-Axis and 5-Axis CNC solutions, designed and built in Colorado Springs.