Diversified Machine Systems

Industrial-grade, 3-Axis and 5-Axis CNC machines made in the USA and backed by the industry’s best customer service.

DMS Product Lines

DMS Essentials 3-Axis

DMS CNC routers offer a universal platform ideal for configurability for a myriad of applications. Our machines feature a large bridge, rails and ball screw which, when combined with a heavier gauge, all-steel frame, results in a machine that is rugged, durable and ideal for high production factories.

DMS Essentials 5-Axis

Is your manufacturing setup unique? Our engineers have over 70 years of combined CNC experience with a proven track record of designing custom CNC solutions. Contact us with your production goals and we will design a machine to fit your floor space and exceed your goals.

Freedom

The Freedom CNC router line offers a universal platform with the rigidity and repeatability required to process many materials, including wood, plastics, foam, aluminum, composites and more. Whatever material you are working with, we can configure and build a CNC router to accurately and efficiently get the job done.

Hybrid

A Hybrid machining center integrates polymer and composite additive manufacturing into our proven, heavy duty 3 and 5-axis router platforms. These versatile machining centers offer a number of manufacturing solutions not available from a traditional subtractive machine.

Industries We Serve

Trusted By Industry Leaders

From the Blog

A New CNC Machine? In This Economy?

It’s a challenging time to consider a big investment. With rising interest rates and the highest interest rates since 2001, fewer people are willing to risk investing in big purchases like a house or car—or a new CNC machine. Today’s interest rates increase the cost...

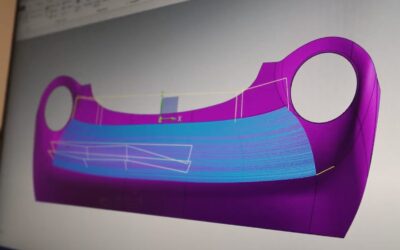

This Custom Router Is about to Leave Our Factory Floor

At Diversified Machine Systems (DMS) we make CNC machines with you in mind. Our lineup of American-made routers is designed to serve a broad range of manufacturing needs, from aerospace to automotive to the defense industry. But our favorite projects begin when a...

Restoring Classic Cars with New Technology

https://youtu.be/HUjmRh8Armw When DMS Solution Architect Jesus Molina was asked to work on a Porsche 914, he knew he had a special project on his hands. The Porsche 914 was originally developed as a collaboration between Porsche and Volkswagen in 1970. Envisioned as a...